Loading . . .

No matches found

The Value of DuPont™ Nomex®: Debunking the Cost Myth.

In any business decision, cost plays a significant role. Despite common misconceptions, the idea that DuPont™ Nomex® is pricier than other market alternatives is often unfounded.

This misconception usually arises from comparing the price per pound or in assuming that thickness alone determines performance. When evaluating the true performance characteristics and value of Nomex®, it becomes evident that it is a cost-effective choice.

DuPont™ Nomex®, a flame-resistant meta-aramid material developed in the 1960’s, has become renowned for its exceptional heat resistance and reliability in safeguarding against high temperatures. Widely used in industries such as power & energy, military & aerospace, mobility, and electrical, Nomex® offers outstanding thermal stability, low thermal shrinkage, and structural integrity even at elevated temperatures.

Now, let’s debunk the myth of Nomex® being too expensive and explore its cost advantage.

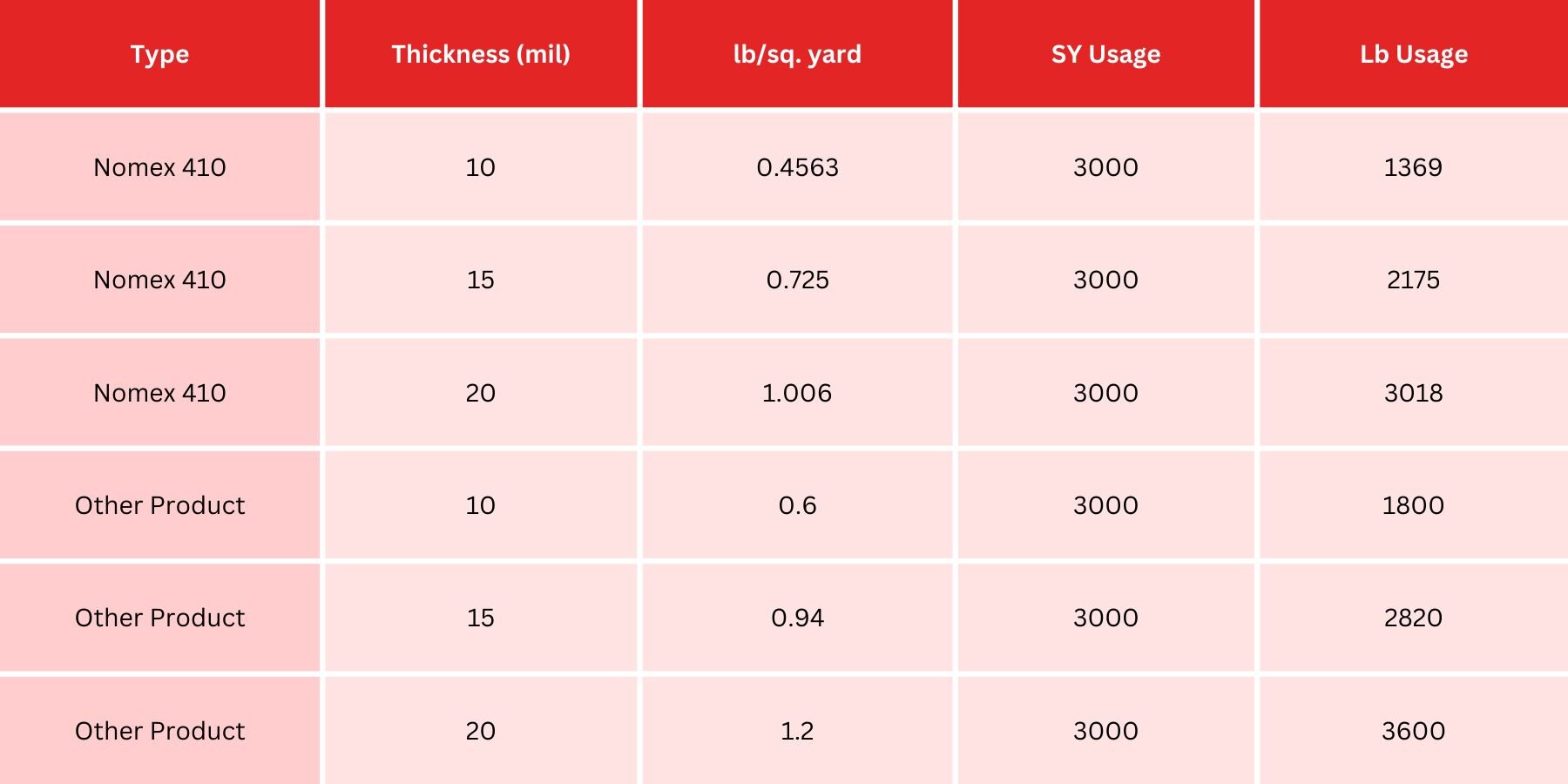

Most every application will require a specified number of square yards (area) of Nomex® -- which means you will want to compare material by the price per square yard instead of the price per pound.

For example, when looking at purchasing 3,000 SY of 10-mil material, a competitive brand would be the equivalent of 1,800 lbs. whereas the equivalent SY of Nomex® 410 is only 1,369 lbs. Simply put, if you were building a transformer or motor that the BOM requires 3,000 SY of insulation paper, you would purchase only 1,369 pounds of Nomex® versus about 1,800 pounds of a competitive material (31% more!) assuming that the performance is equal at the same thicknesses.

Additionally, while some alternatives may appear to be less expensive initially, they may not offer the same level of performance as DuPont™ Nomex®. By carefully considering the requirements of each application, users can make informed decisions that align their needs with the unparalleled capabilities of Nomex®. One can discern that a lower mil thickness of a Nomex® product may offer superior performance in one or more of the categories of properties, creating more value and long-term cost savings.

For instance, there may be times where it is appropriate to use a 5 or 7-mil Nomex® 410 in place of a 10-mil thick competitive material, which would further reduce the weight of the Nomex® that you would be required to purchase. Opting for a lower mil thickness of a Nomex® product can often deliver the ideal solution, offering unmatched value and long-term cost savings as well as, potentially, increasing your overall performance and life expectancy of the product.

Nomex® can offer a true-cost advantage when its exceptional performance and value are taken into account, despite misconceptions about its pricing.

By prioritizing specific properties and tapping into the invaluable

partnership between DuPont™ Nomex® and Essex Brownell, businesses can use

our combined expertise to find perfect solutions.

Essex Brownell stands firmly behind DuPont™ Nomex® and its commitment to

excellence. Also, as an esteemed provider of Essex Active converting and

fabricating services, Essex Brownell seamlessly integrates DuPont™ Nomex®

into its operations. By leveraging the exceptional properties of Nomex®,

Essex Brownell delivers tailored solutions that meet customers' unique

requirements.

As a global leader, Essex Brownell has the capability and the expertise to

exceed your expectations for your unique project. Work with us and

experience the difference!